An extensive study of the application of geopolymer concrete was commissioned by the Port of Rotterdam Authority.

The Port of Rotterdam Authority has the ambition to reduce its CO2 emissions by 25% by 2030. One possibility concerns the use of more sustainable materials. It is known that traditional concrete (TB) based on Portland cement shows high CO2 emissions. Therefore, in recent years much attention has been focused on more sustainable types of concrete. An interesting option here is concrete with an alkaline activated binder, better known as geopolymer concrete (GPB). The Port of Rotterdam Authority has started a pilot project to explore whether the application of GPB in port structures is possible. This involves determining the performance properties of GPB (with and without fibers). At the request of the Port of Rotterdam Authority, SGS INTRON has carried out the project and prepared the final report.

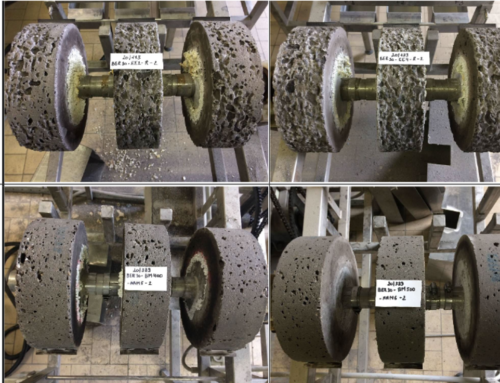

The extensive testing program provided broad insight regarding the properties of the applied geopolymer concrete (GPB); these are compared with expected values of traditional concrete (TB). One mixture with and one mixture without fibers were investigated. The full report can be requested from Sqape or Port of Rotterdam Authority.

Following the results achieved, the first quay walls made of geopolymer concrete will soon be realized in the port of Rotterdam.